Silk is unique by the very process of its formation

The threads spun by the silk moth Bombyx mori, which translates as the “silkworm of the mulberry tree”, are regarded as the highest quality. These silks have the longest thread because the cocoons are harvested whole before the caterpillars hatch. It takes about four weeks for the cocoons to be large enough to undergo heat treatment.

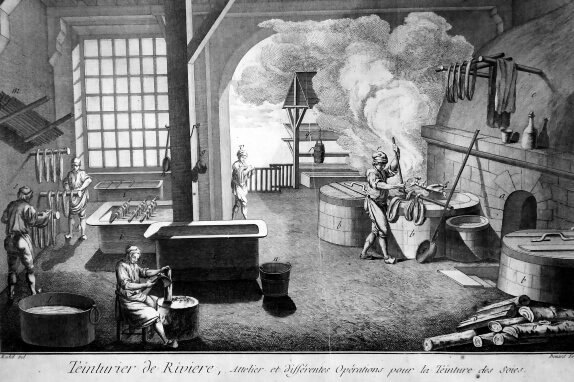

In order to obtain the thread, the cocoons are treated with hot steam then immersed in hot water and brushed. This process dissolves the Silk Gum – the secretion from the caterpillar which glues the threads together to form the cocoon – to leave a fine, smooth thread. This reeling process is carried out on three to eight cocoons at once. This produces about 300 to 800 m of raw silk yarn which is woven on the loom into different high-quality grades, such as Silk Taffeta. The resulting waste products are also processed, often into bourette silk.

| Properties which make silk so incomparable:

|

“Silk is tougher than steel.

The resistance of this material is quite incredible.”

Edgar Nierentz, former authorised signatory (Prokurist)

The most important link in the silk production chain is the

The most important link in the silk production chain is the

silk moth which supplies the silk for cultivated silk or mulberry silk production. The caterpillar tirelessly spins a cocoon, shedding its skin a total of four times in the process, and is ready to spin about 35 days after hatching from the egg.

The caterpillar has silk glands formed from multiple strands wound into tube-like structures which secrete a substance from the rear consisting of special proteins. The resulting silk material is routed through thin passages to a spinneret on the head of the caterpillar. The secretion emerging from this gland immediately hardens into a thread when it comes into contact with the air.

The caterpillar moves its head steadily during this secretion process, thereby wrapping the thread around itself and building a stable cocoon for itself from this filament. The caterpillar winds the thread around itself up to 300,000 times. It is fascinating that this cocoon is made of a thread up to 900 metres long!

In order to produce the silk, the caterpillars are killed in hot water or steam before hatching. This is to prevent the cocoon from tearing. The individual filaments stick together because of the silk gum and thereby form the silk thread, also called grège. The silk is washed in boiling soapy water in order to remove the yellowish glue. This process is also called scouring or degumming.

Afterwards it appears whitish and is thinner, shinier and more supple. Finally, silk is put through further chemical treatment processes, such as sulphur dioxide treatment which bleaches the silk.